|

|

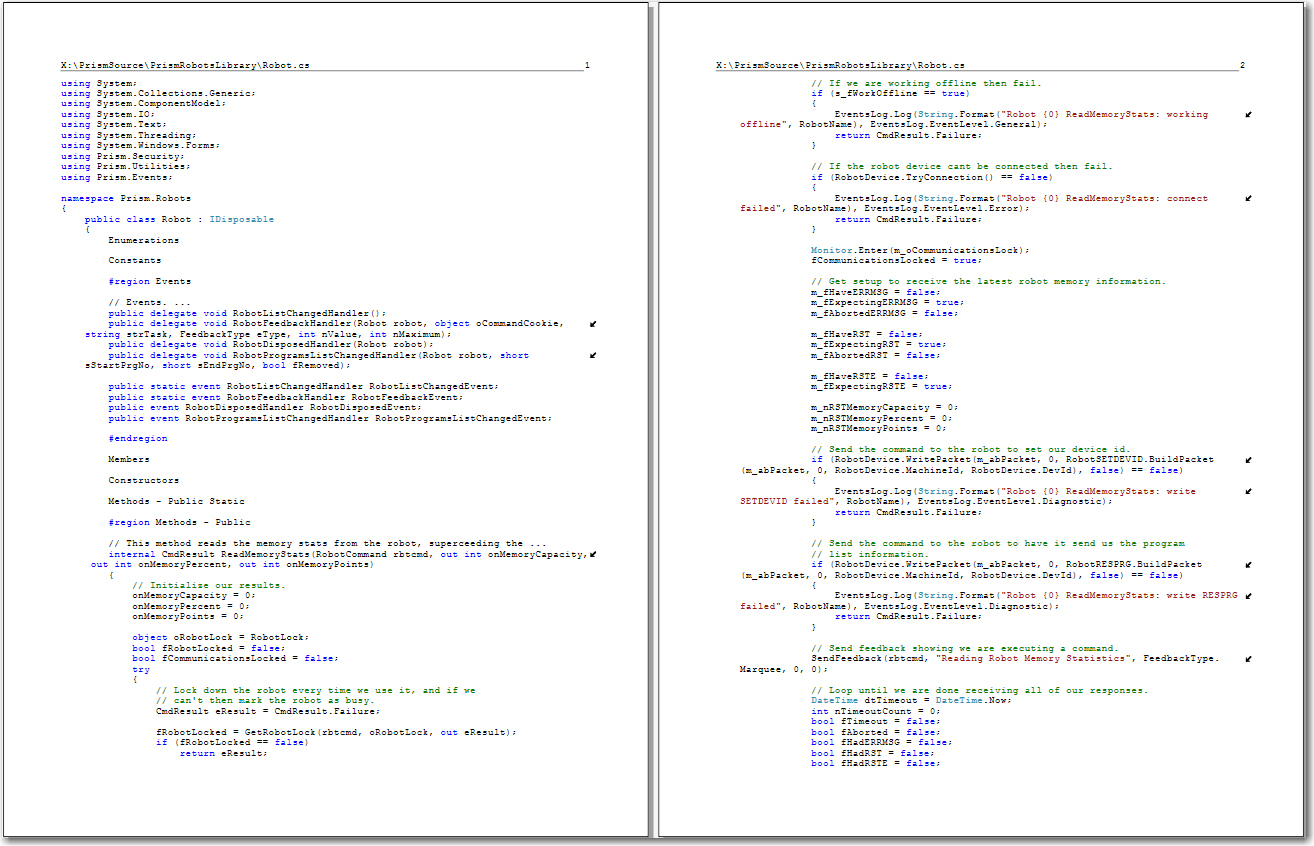

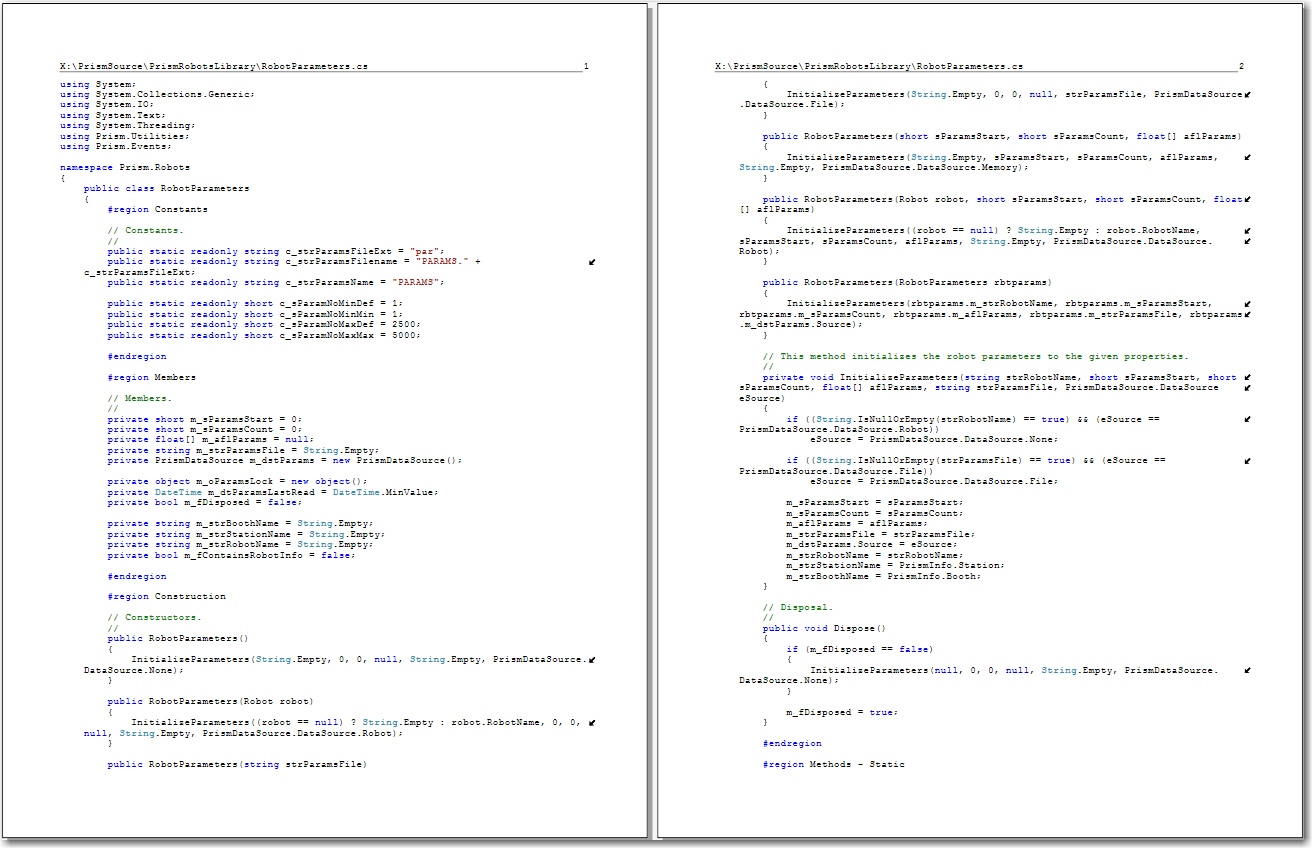

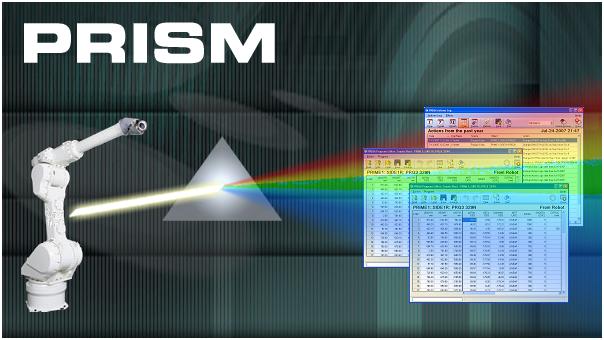

PRISM is a Windows-based HMI interface for the Kawasaki paint robotics system used within many auto manufacturing paint facilities, including Toyota and NUMMI. The interface allows users to create, manage, modify, backup, restore and delete the robot motion programs and parameters on the many robot controllers. View the PRISM Training Slides for screen shots and a functional overview. View the PRISM User Documentation for a detailed functional description. PRISM was created to replace an existing interface program that had become unreliable due to its age and design limitations. Created using VB 4.0 for Windows 95, the rigid architecture of the existing program continuously failed on modern, faster computers. PRISM was developed using Visual Studio 2005, and is written in C# with Microsoft .NET 2.0. Its object oriented design makes heavy use of inheritance, allowing consolidation of common features into root classes. Designed by Jim Shaffer, Pioneer Software’s senior software architect, PRISM is a combination of the required features from the existing interface, the requested features from the customer and features recommended by Pioneer Software’s architects. The resulting interface package has proven itself to be extremely robust, completely reliable and intuitive to use. PRISM uses a ringed architecture, with a central communications library at the inner most ring. The communications library is responsible for sending and receiving the serial communications with the robot controllers. It ensures reliable communications by automatically resolving anomalies using retransmission, reconnection, or as a last resort to notify the user of the anomaly. Surrounding the communications library is the command library. It accepts robot command requests from the outer rings, queues the commands to ensure they are issued sequentially to the robot, and that all expected command responses are received. Surrounding the command library are the user interface forms. The forms send commands as necessary to the command library and wait for command responses when appropriate. Because the command library and communications library sequence all communications traffic with the robots, the user interface can seem to perform multiple tasks simultaneously. This allows the interface to be used intuitively in whatever manner best suits the user's needs and work style. PRISM Design / Development Challenges PRISM Documentation PRISM Sample Source Code PRISM Statistics

|

|

||||||||||||||

|

|

||||||||||||||||

View Portfolio |

|||||

|

|

|||||

|

|